[QUOTE=SteveS] I just bought a dial indicator and I'm about to start measuring stiffness.[/QUOTE]

Steve,

Given your post title and all of the spam viagra e-mails I seem to be getting, you had me wondering for a moment there bro

| Official Luthiers Forum! http://www-.luthiersforum.com/forum/ |

|

| Stiffness measuring newbe questions. http://www-.luthiersforum.com/forum/viewtopic.php?f=10102&t=8700 |

Page 1 of 1 |

| Author: | Steve Saville [ Wed Oct 04, 2006 5:22 am ] |

| Post subject: | |

I just bought a dial indicator and I'm about to start measuring stiffness. I'm thinking of using a couple of dowels and a board with notches to place the dowels at about 6", 8" and 12" apart would be a good start. I'm also thinking that in addition to measuring plates and braces, measuring assembled tops and backs is a good idea. So, I'm looking for so advice on how to measure - what to do and what to avoid. Any pictures would be greatly appreciated. Thanks! |

|

| Author: | Dave White [ Wed Oct 04, 2006 5:46 am ] |

| Post subject: | |

[QUOTE=SteveS] I just bought a dial indicator and I'm about to start measuring stiffness.[/QUOTE] Steve, Given your post title and all of the spam viagra e-mails I seem to be getting, you had me wondering for a moment there bro

|

|

| Author: | Michael Dale Payne [ Wed Oct 04, 2006 5:48 am ] |

| Post subject: | |

For braces I would use 12" spacing on the support rods, as most of your critical brace lengths on Om-dreads will be in the 14"-18" finished length. this way your measuring close to the beam length you are actually using. Whatever means of deflection weight you use needs to remain constant in both mass and area so that you always compare apples to apples. Also I would rig my test fixture to measure on the bottom edge as opposed to the top edge so that you can measure dead on the apex of the deflection. If you measure from the top you have move of the apex to clear the weights foot print. |

|

| Author: | dgalas [ Wed Oct 04, 2006 6:03 am ] |

| Post subject: | |

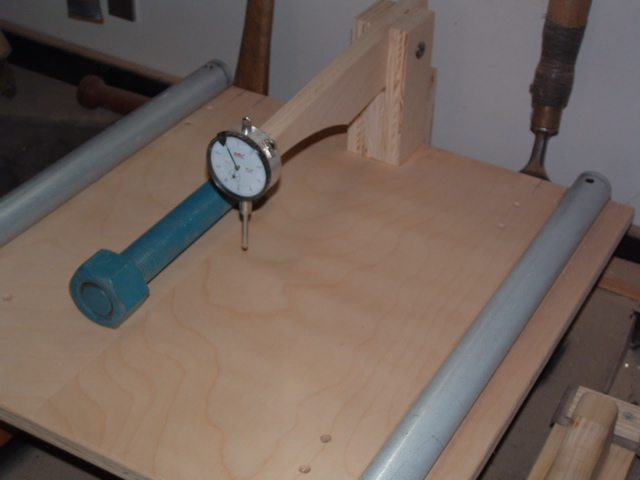

Steve, The key is consistency. Make sure your dowels are always in the same place and the weight you use is the same for every measurement of a certain kind. I have my 'dowels' (actually metal tubes from the scrap yard) set at 16" apart for measuring top plate deflection. The weight I use is a big blue bolt (scrap yard). I have no idea how much it weighs, but I always use the same bolt so my numbers are consistent. Here's my set up:

|

|

| Author: | nickton [ Wed Oct 04, 2006 6:08 am ] |

| Post subject: | |

duuh. Why do you need this thing? |

|

| Author: | Michael Dale Payne [ Wed Oct 04, 2006 6:53 am ] |

| Post subject: | |

To verify deflection in tops, backs or braces stock to use as a relative baseline comparison of stiffness properties |

|

| Author: | Brock Poling [ Wed Oct 04, 2006 7:17 am ] |

| Post subject: | |

[QUOTE=nickton] duuh. Why do you need this thing?[/QUOTE] You want to measure longitudinal stiffness. Depending on what methodology you are using this helps to determine target thickness of your plate. |

|

| Author: | John How [ Wed Oct 04, 2006 7:42 am ] |

| Post subject: | |

Very nice looking jig/setup Dave. |

|

| Author: | Alan Carruth [ Wed Oct 04, 2006 7:48 am ] |

| Post subject: | |

Dave Hurd's 'Left Brain Lutherie' book goes into excruciating detail on this, at all stages of construction. He includes equations for finding things like the Young's modulus from your deflection data, which makes it possible for you to compare your results with other folks, and thus learn faster. |

|

| Author: | Steve Saville [ Wed Oct 04, 2006 8:04 am ] |

| Post subject: | |

[QUOTE=MichaelP] .....I would rig my test fixture to measure on the bottom edge as opposed to the top edge so that you can measure dead on the apex of the deflection. [/QUOTE] Thanks, Point taken. That shouldn't bee too hard to do. |

|

| Author: | nickton [ Wed Oct 04, 2006 9:42 am ] |

| Post subject: | |

So how thick does a spruce top generally need to be? Do you need this device to figure it out every time? I also wonder how this affects bracing size and placement. I have much to learn obviously. Someday I may get that book...I'm just learning to fly by the seat of my pants and duplicating what's on my other guitars. |

|

| Author: | Billy T [ Wed Oct 04, 2006 3:12 pm ] |

| Post subject: | |

Steve! Your a noob? No way - I've seen your work! What are the main findings of stiffness? You want high/low/in between. Intuitiveness, sounds as if it may be unreliable in this case.(Now that is a noob question) Billy Dean Thomas |

|

| Author: | Brock Poling [ Wed Oct 04, 2006 4:10 pm ] |

| Post subject: | |

[QUOTE=nickton] So how thick does a spruce top generally need to be? Do you need this device to figure it out every time? I also wonder how this affects bracing size and placement. I have much to learn obviously. Someday I may get that book...I'm just learning to fly by the seat of my pants and duplicating what's on my other guitars.[/QUOTE] Again, it depends on your philosophy. Some build to target thickness. Once it hits .XXX" it is time to stop. Others build to target deflections. Put the plate on the deflection rig, test it, sand, retest it, etc. Until you hit a given deflection. In this situation every plate is different. Some might be .125" others might be .068" (as the crowd feints...  ). This methodology takes into consideration that every piece of wood is different. ). This methodology takes into consideration that every piece of wood is different.

|

|

| Author: | Alan Carruth [ Thu Oct 05, 2006 5:08 am ] |

| Post subject: | |

Stiffness _ratio_ counts too. With a top that has higher crosswise stiffness you can rune the braces more 'along' the grain, and make the top a little lighter. It's a game of inches, or, maybe, grams. |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|